Raniganj, Bardhaman, West Bengal

- GST NO. : 19ADIPB5886A1ZL

View Mobile Number

| Business Type | Manufacturer, Exporter, Supplier, Trader, Importer |

| Country of Origin | India |

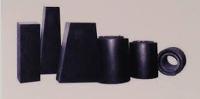

| Type | Silicon Carbide Brick |

| Material | Silicon Carbide |

| Click to view more | |

Product Details

Silicon Carbide refractories are produced from silicon carbide, a raw material synthesized in a resistance-type electric furnace at temperature exceeding 2500°C, through the reaction of silica with carbon. They have a thermal conductivity ten times that of fireclay refractories, good corrosion and thermal shock resistance, and can be formed into complex shapes. They can withstand slag attack and flame erosion. This makes CUMIFRAC unusual even among advanced refractories and has given it wide uses.

Outstanding Features

- Extremely high thermal conductivity

- Very high hot strength

- High erosion and abrasion resistance, thermal shock resistance

- Chemical inertness

Specifications

| User Industries | Application |

| H.T. Insulators / Ceramics | Kiln furniture |

| Sanitaryware | Muffles and chamber-fronts |

| Ferro-alloys | Taphole linings |

| Foundries, Forge plants, Powder metallurgy | Heat treatment furnace hearth |

| Product | A.P (%) | B.D (gm/cm3) | C.C.S (kg/cm2) | RUL Ta (°C) | Al2O3(%) | SiC (%) | Fe2O3(%) |

| SiC 80 | 19 | 2.45 | 600 | 1500 | 15 | 80 | 1.2 |

| SiC 85 | 16 | 2.60 | 800 | 1550 | 12 | 84 | 0.9 |

The above figures are typical data as determined through Indian Standard Testing Methods and pertains to most commonly procured commercial sizes. These will be subject to reasonable variations for tailor made and non-standard sizes.

Materials can be manufactured to suit customer's specifications.

Looking for "Silicon Carbide Bricks" ?

Explore More Products

Our Blogs